Single-Ply Roof Coverings

The single-ply family of roofing materials includes some distinctly different products.

(Modified bitumen products [Art. 12.4.4] are sometimes included in the singleply category.) The single-plies can be classified as either thermoset or thermoplastic materials. Thermoset materials normally cross-link (cure) during manufacturing.

Once cured, these materials can only be bonded to themselves; for example, at a seam. Bonding is accomplished with an adhesive. Thermoplastic materials do not cross-link. Therefore, they should be capable of being welded together throughout their service life. Welding is usually accomplished with hot air.

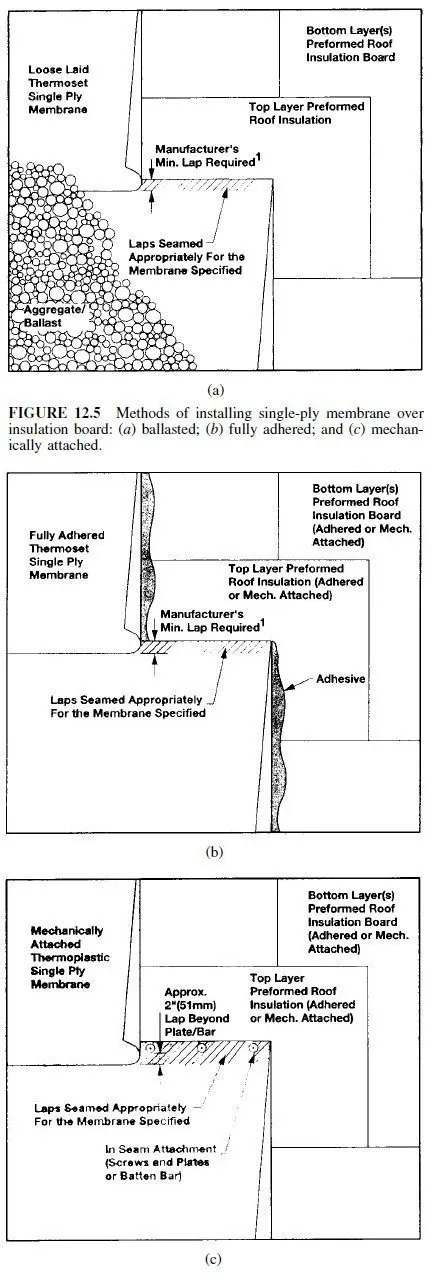

There are three primary methods for attachment of single-ply membranes to a roof deck. In the ballasted system, the membrane is laid loose over the substrate and then covered with ballast to resist uplift from the wind (Fig. 12.5a). The ballast can either be large aggregate or concrete pavers. In the second method of attachment, the membrane is fully adhered in a continuous layer of adhesive (12.5b). In the third method, the membrane is mechanically attached to the deck (Fig. 12.5c).

The mechanically attached system generally utilizes screws with stress plates, or metal batten bars, located within the membrane lap (seam). Alternately, the battens may be placed on top of the membrane and covered with a stripping ply of the membrane material. There are other variations of the mechanically attached system, many of which are proprietary to a single membrane manufacturer.

Following are descriptions of single-ply membrane materials.

Chlorosulfonated polyethylene (CSPE) is commonly known by the trade name Hypalon. It is a thermoset product, but it cures after installation on a roof. This product is specified in ASTM D5019 (Type I). It is usually supplied in a white color.

Ethylene propylene diene terpolymer (EPDM) is a synthetic rubber membrane.

It is a thermoset product specified in ASTM D4637. This standard includes specifications for Type I, non-reinforced; Type II, scrim (or fabric) internally rein forced, and Type III, fabric backed. It is available in a white color, but black is used most often.

Polyisobutylene (PIB) is a thermoplastic product, specified in ASTM standard D5019 (Type II). It is available in a black or white color.

Polyvinyl chloride (PVC) is a thermoplastic product, specified in ASTM D4434. Different types and grades are specified in ASTM D4434 and identify a membrane by the type and location of the reinforcement or fabric backing. It is available in a variety of colors.

PVC blends (also known as copolymer alloys) are based on PVC resin. They are similar to PVC membranes. The next revision of ASTM D4434 will probably also cover PVC blends.

Thermoplastic polyolefin (TPO), as the name denotes, is a thermoplastic product containing polyolefin polymers. TPOs are newer to the marketplace in the United States; however, variations of this membrane have been used in Europe for many years. Currently, an ASTM standard is being drafted for this single-ply membrane product.